As architects, you’re not just creators of spaces but custodians of the future environment. Sustainability is the keystone of contemporary architecture, guiding both design philosophy and construction practices. And among the most critical aspects of sustainable design is embodied carbon, a metric that evaluates the environmental impact of the materials and methods we employ from the ground up.

In this blog, we delve into the significance of embodied carbon in the sustainability narrative and investigate how it can serve as a benchmark for the green credentials of our new buildings. Let’s get started, shall we?

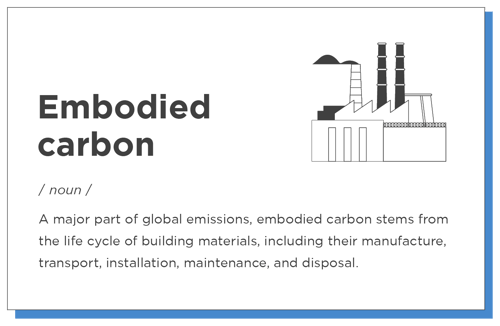

Understanding embodied carbon

“In the building industry, embodied carbon refers to the greenhouse gas emissions arising from the manufacturing, transportation, installation, maintenance, and disposal of building materials. In contrast, operational carbon refers to the greenhouse gas emissions due to building energy consumption.” – Carbon Leadership Forum

The Paris Agreement has set a threshold: to prevent a disastrous shift in our climate, we must cap the rise in average global temperatures at 2°C. The building industry is responsible for 39% of annual CO2 emissions, and embodied carbon alone accounts for 11% of global annual emissions. With atmospheric carbon accumulation and a narrowing window to avert the tipping point, the carbon we emit today weighs heavier on our climate's fate than carbon released in the future.

Most of a building's embodied carbon emissions occur during the product stage, marking the beginning of its life cycle. Unlike operational carbon, which can be reduced over time through energy-efficient measures, embodied carbon is fixed once construction is complete, with no retroactive solutions available. This makes the decisions made during the design and material selection phases crucial, as they have immediate and lasting environmental consequences.

Considering our immediate and long-term climate goals, addressing embodied carbon from the initial stages of design is essential.

Addressing embodied carbon

Effectively reducing embodied carbon in new constructions hinges on choosing the appropriate materials. Ideal materials should be:

Durable and reusable

Using more durable materials means a longer building lifecycle and less need for repairs. It also increases the ability to re-use the materials when the building does reach its end of life. For example, if a material can withstand greater loads or stresses, it may be possible to use less of it to achieve the same structural performance, thus reducing the embodied carbon associated with material volume.

Made of wholly or partially recycled materials

Using recycled materials can extend the lifetime of raw materials and reduce the need for extraction of new materials from the earth — which, in turn, reduces the energy required to produce new materials. For example: substituting cement with slag, fly ash, or other pozzolanic or lime-based materials can reduce embodied carbon by 14–33% at no cost or even a cost reduction.

Sourced and/or produced locally

If materials — virgin or recycled — are sourced locally, the energy and emissions associated with transportation can be significantly reduced compared to shipping materials from potentially distant locations. The further a material must be transported, the more energy is used, and the greater the emissions are from the vehicles used for transportation.

We have both the privilege and the responsibility of shaping the environmental legacy we leave behind. By making informed decisions in the design phase, selecting sustainable materials, and adopting innovative construction techniques, we can significantly mitigate the environmental impact of our creations.

Every step we take towards reducing embodied carbon is a stride towards a more sustainable and resilient future. Let us not underestimate the power of our choices and the positive ripple effect they can have on the world.